Automate Your Business Case

Our configurator combines project costs, time schedules and expected revenues to automatically generate a discounted cash flow (DCF) model that is tailored to the specific deal structure, equity share and exit scenario of your business case.

Our configurator combines project costs, time schedules and expected revenues to automatically generate a discounted cash flow (DCF) model that is tailored to the specific deal structure, equity share and exit scenario of your business case.

Project financials, the design and the programme all correspond to a single source of truth. This allows for diverse scenarios to be tested and project information to be updated simultaneously as a result of any changes.

Rabbit Real Estate & ZHAW win Innosuisse SME Innovation Project Grant

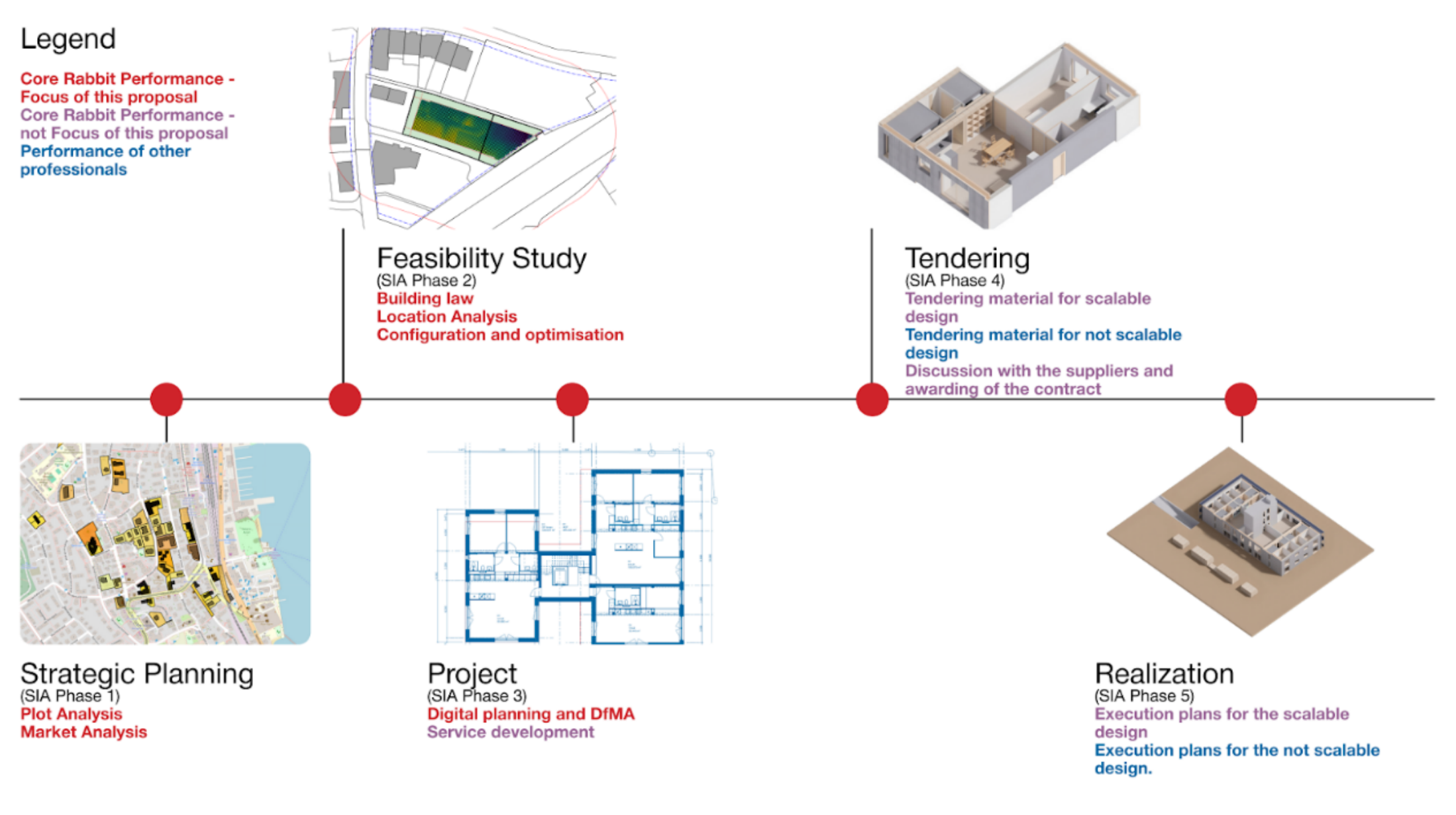

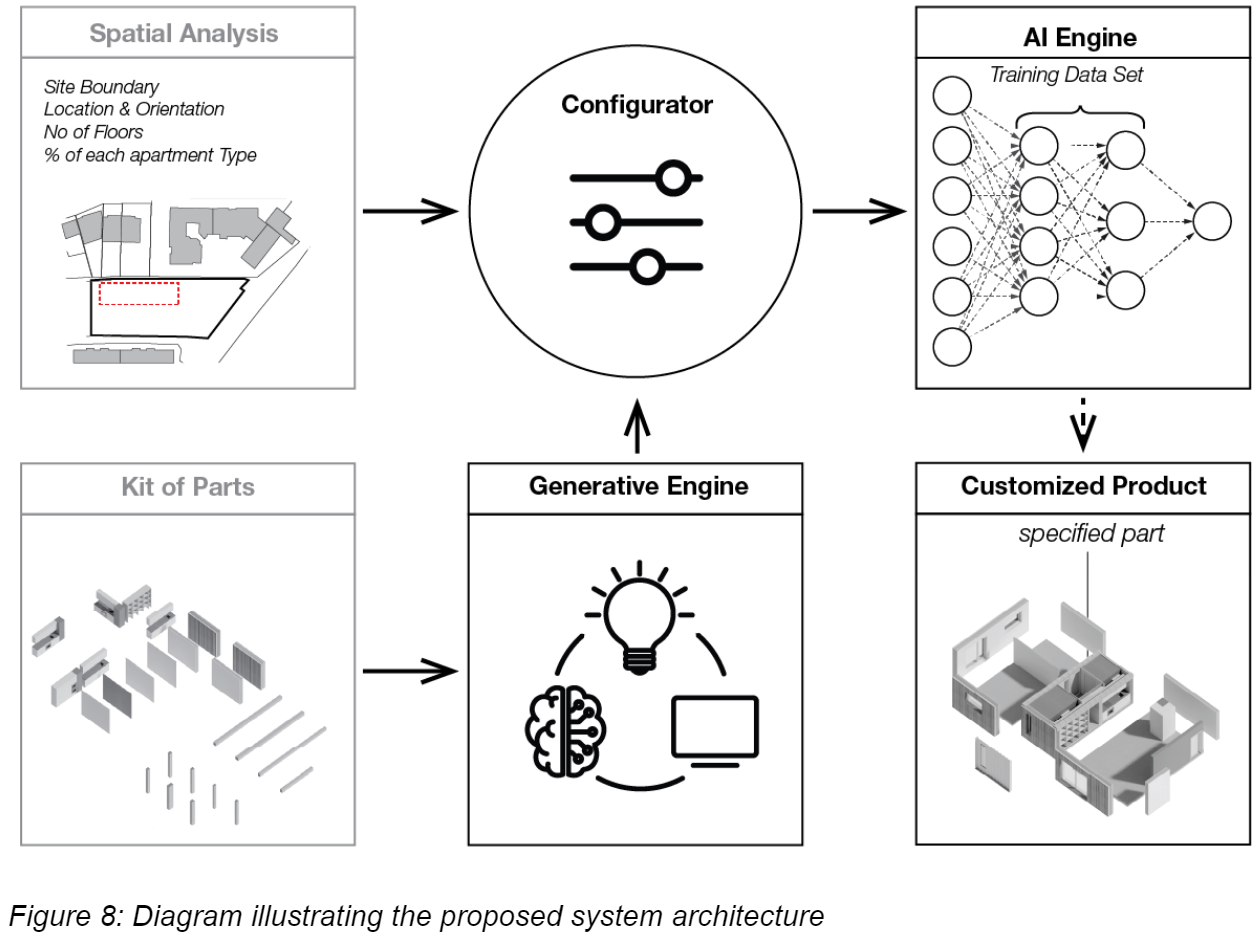

We are thrilled to announce that, together with our colleagues Konrad Graser, Evangelos Pantazis, Ph.D. & Pavel Sulimov from the ZHAW Zurich University of Applied Sciences, Rabbit Real Estate has been selected for an innovation project grant from the Swiss Innovation Agency Innosuisse. The purpose of the grant is to co-develop a digital end-to-end configurator for residential real estate development.

We are thrilled to announce that, together with our colleagues Konrad Graser, Evangelos Pantazis, Ph.D. & Pavel Sulimov from the ZHAW Zurich University of Applied Sciences, Rabbit Real Estate has been selected for an innovation project grant from the Swiss Innovation Agency Innosuisse. The purpose of the grant is to co-develop a digital end-to-end configurator for residential real estate development.

We are grateful to have been selected from among 270 applicants and look forward to fully using this opportunity to bring more innovation and digital integration to the real estate and construction industry.

Thank you to Innosuisse for this opportunity and to our partners Konrad Graser, Evangelos Pantazis, Ph.D., Pavel Sulimov and the ZHAW Zurich University of Applied Sciences for the successful application and collaboration. We look forward to working together!

We would like to echo the words of Innosuisse CEO Dominique Gruhl-Begin: "Dare to take the plunge, even when times are tough".

Top-down & Bottom-up

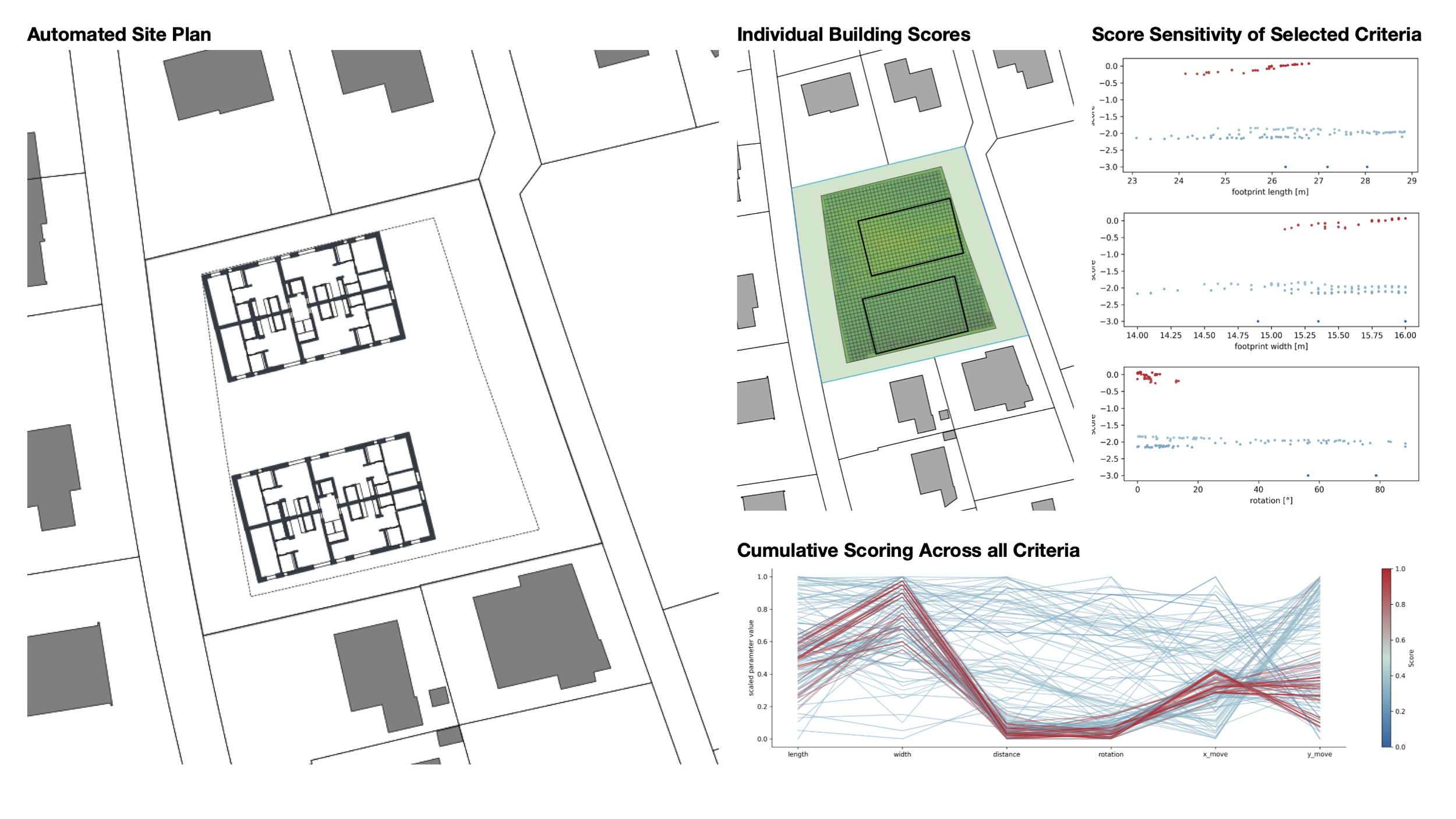

Optimising a housing project is a complex, iterative process. It requires a great deal of fine-tuning and cross-scalar trade-offs between different goals and parameters. Our configurator helps expedite this by automating and evaluating iterations according to a scoring system.

Optimising a housing project is a complex, iterative process. It requires a great deal of fine-tuning and cross-scalar trade-offs between different goals and parameters.

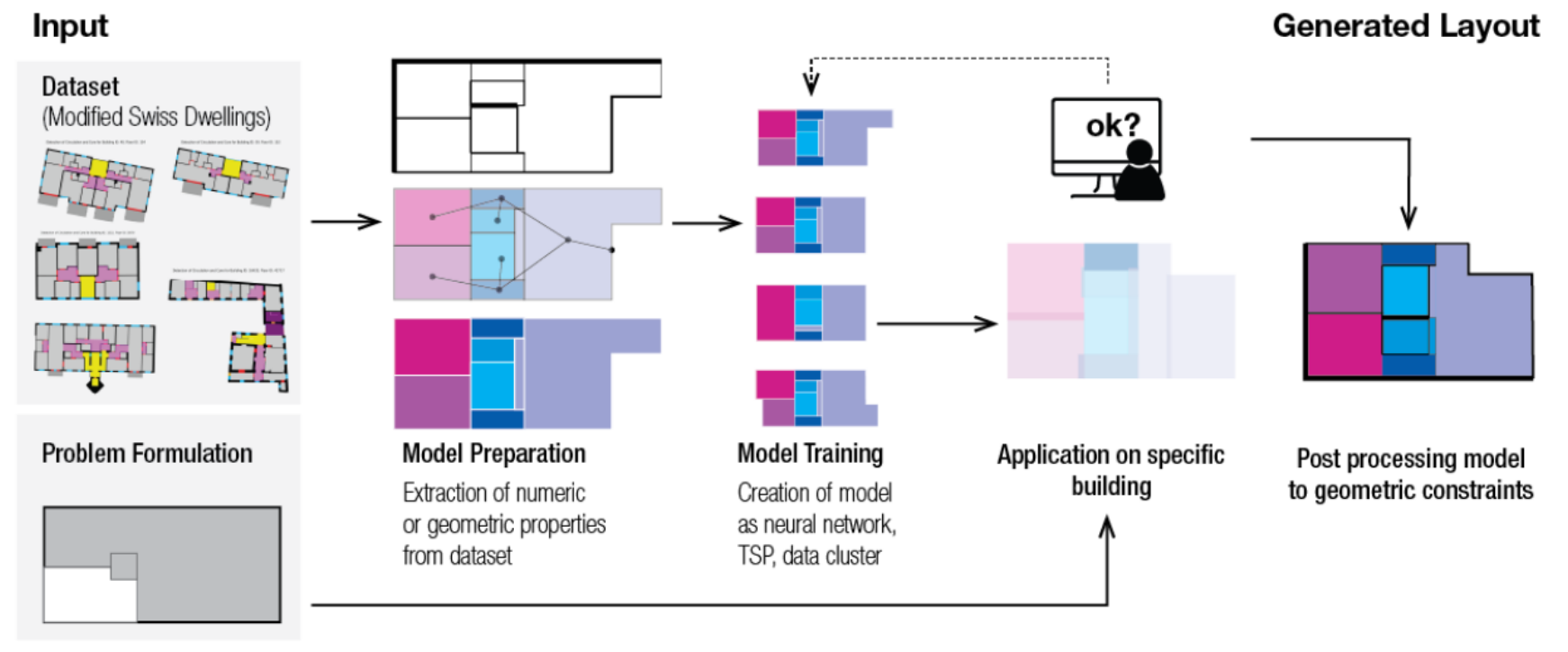

Our configurator helps expedite this by automating and evaluating iterations according to a scoring system. Building volumes are simultaneously positioned "top-down" in response to geo data, spatial analysis and planning regulations, whilst also laid out "bottom-up" using a single kit-of-parts within a modular construction system.

Together, this multi-scalar approach maximises plot utilisation and floor area efficiency, provides the ideal unit mix and thereby optimises risk-adjusted returns. This is just one way in which we want to make decision-making more dependably data-driven.

Configure. Automate. Optimise.

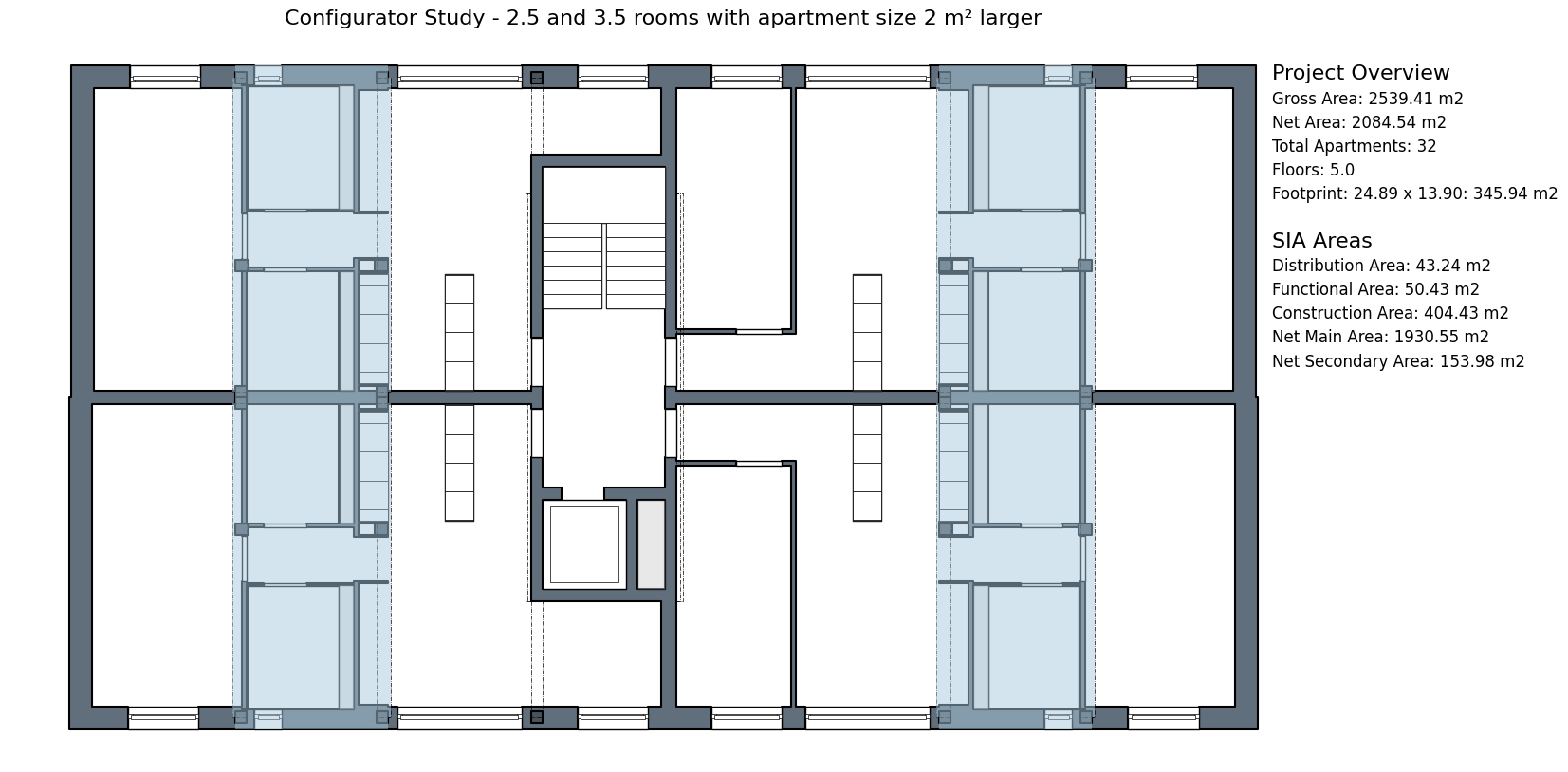

Our Python-based configurator uses a kit-of-parts to generate a wide range of potential floor plan solutions based on project inputs (target unit mix & sizes, plot geometry and the maximum realisable area or volume) within minutes.

Our Python-based configurator uses a kit-of-parts to generate a wide range of potential floor plan solutions based on project inputs (target unit mix & sizes, plot geometry and the maximum realisable area or volume) within minutes. This automated process includes key output metrics such as floor area categories, unit and room sizes.

Stay tuned to see how we use this approach to further optimise floor area efficiency and economic performance, as well as providing reliable data on costs, LCA and construction time - all at a feasibility study stage.

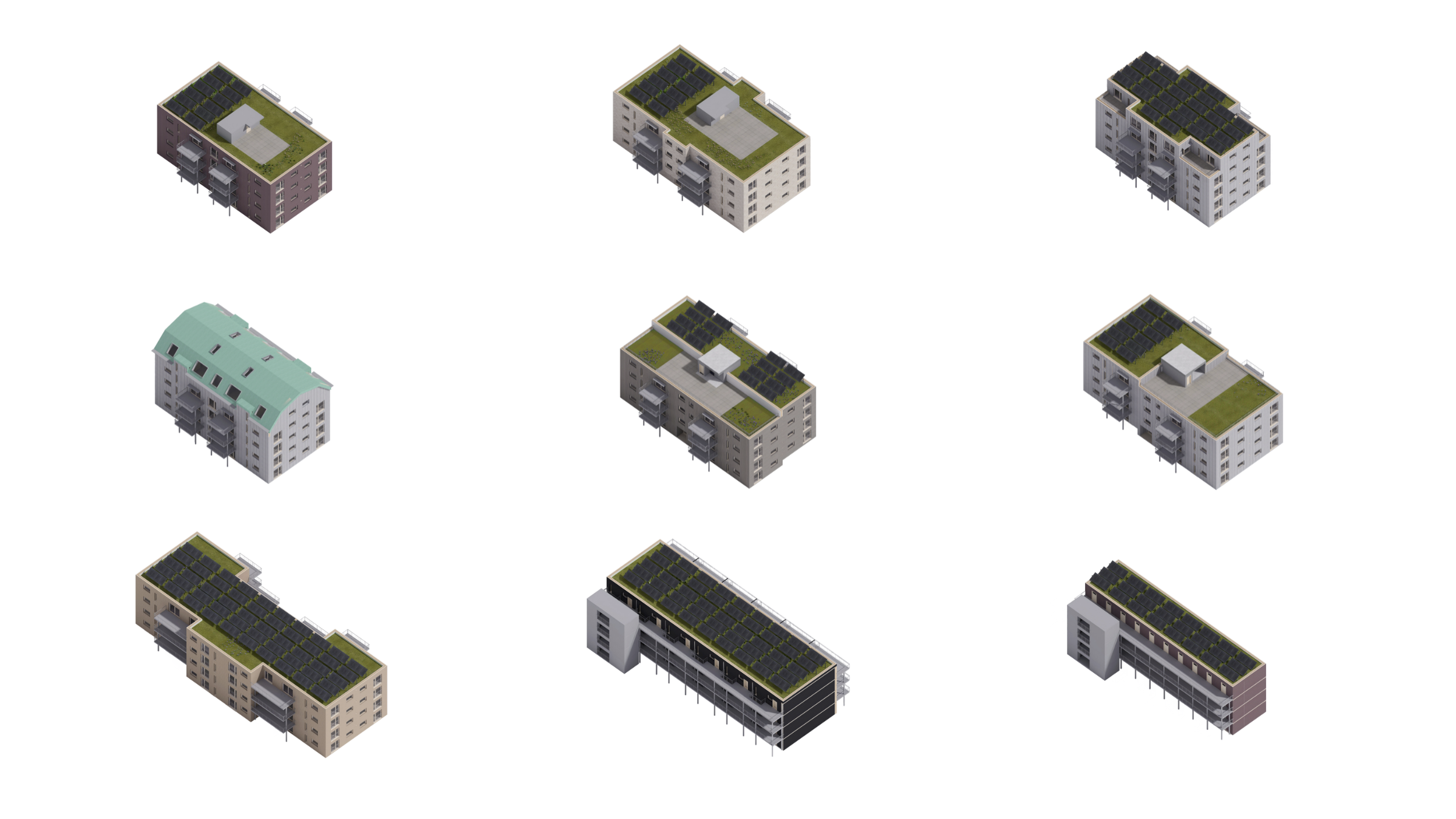

Variety in a Systematised Approach

Prefabrication and variety are not mutually-exclusive.

In fact, the design may even become richer - because it tells the story of how a building and its pieces were made and put together.

Prefabrication and variety are not mutually-exclusive. Whilst additional production and assembly constraints may restrict what is possible, site- & project-specific responses, regulatory and life-cycle considerations, as well as varied architectural expression in terms of material, rhythm, pattern, scale and colour, are all still possible.

In fact, the design may even become richer - because it tells the story of how a building and its pieces were made and put together.

Pre-fab is not what it used to be

Gone are the days when modular, pre-fabricated housing has to be associated with unfeeling and drab concrete boxes. This is what the new era of pre-fab looks and feels like.

Visual of a 4-room corner unit

Visual of a 3-room through-put unit

Gone are the days when modular, pre-fabricated housing has to be associated with unfeeling and drab concrete boxes. Pre-fabricated timber construction is not only more lightweight and sustainable, but creates a warm atmosphere with natural surfaces and a beneficial indoor climate. The simple and honest structural design is made legible in the exposed columns and beams that also delineate interior spaces.

Our partners' innovative manufacturing processes and our system-based approach also allow for a range of configurable interior design lines with variable ceiling and floor materialities, colour ranges and built-in furniture modules.

This is what the new era of pre-fab looks and feels like.

Neither Cookie-Cutter nor One-Off Prototype

Prefabricated housing does not have to be "cookie-cutter". Society cannot afford to, nor does it need to, develop every multi-family home as a one-off "prototype".

Systematised construction and variety are not mutually exclusive.

Prefabricated housing does not have to be "cookie-cutter". Society cannot afford to, nor does it need to, develop every multi-family home as a one-off "prototype".

Thanks to industrialised construction and mass customisation, parts and processes can be standardised while still allowing for configurable solutions that enable architectural expression and the fulfilment of project-specific programme requirements, as well as adaptation to site-specific conditions such as noise, orientation, topography and local building regulations.

Systematised construction and variety are not mutually exclusive.

Best of both Worlds: 3D Modular & 2D Panelised

𝖶𝖾 𝗎𝗌𝖾 𝖺 𝖼𝗈𝗇𝗌𝗍𝗋𝗎𝖼𝗍𝗂𝗈𝗇 𝗌𝗒𝗌𝗍𝖾𝗆 𝗂𝗇 𝗐𝗁𝗂𝖼𝗁 𝖺𝗅𝗅 𝖼𝗈𝗆𝗉𝗅𝖾𝗑 𝖾𝗅𝖾𝗆𝖾𝗇𝗍𝗌 𝖺𝗋𝖾 𝗉𝗋𝖾𝖿𝖺𝖻𝗋𝗂𝖼𝖺𝗍𝖾𝖽 𝗈𝖿𝖿-𝗌𝗂𝗍𝖾 𝗂𝗇 𝟥𝖣 𝗍𝗂𝗆𝖻𝖾𝗋 𝗆𝗈𝖽𝗎𝗅𝖾𝗌. 𝖳𝗁𝖾𝗌𝖾 𝖺𝗋𝖾 𝗍𝗁𝖾𝗇 𝖺𝗌𝗌𝖾𝗆𝖻𝗅𝖾𝖽 𝗈𝗇-𝗌𝗂𝗍𝖾 𝗍𝗈𝗀𝖾𝗍𝗁𝖾𝗋 𝗐𝗂𝗍𝗁 𝗌𝗂𝗆𝗉𝗅𝖾, 𝖿𝗅𝖾𝗑𝗂𝖻𝗅𝖾, 𝗉𝗋𝖾𝖿𝖺𝖻𝗋𝗂𝖼𝖺𝗍𝖾𝖽 𝟤𝖣 𝗉𝖺𝗇𝖾𝗅𝗌. 𝖨𝗇 𝗌𝗈-𝖽𝗈𝗂𝗇𝗀, 𝗐𝖾 𝗈𝗉𝗍𝗂𝗆𝖺𝗅𝗅𝗒 𝗅𝖾𝗏𝖾𝗋𝖺𝗀𝖾 𝗍𝗁𝖾 𝖻𝖾𝗇𝖾𝖿𝗂𝗍𝗌 𝗈𝖿 𝖽𝗂𝖿𝖿𝖾𝗋𝖾𝗇𝗍 𝗍𝗒𝗉𝖾𝗌 𝗈𝖿 𝗉𝗋𝖾𝖿𝖺𝖻𝗋𝗂𝖼𝖺𝗍𝗂𝗈𝗇.

𝖶𝖾 𝗎𝗌𝖾 𝖺 𝖼𝗈𝗇𝗌𝗍𝗋𝗎𝖼𝗍𝗂𝗈𝗇 𝗌𝗒𝗌𝗍𝖾𝗆 𝗂𝗇 𝗐𝗁𝗂𝖼𝗁 𝖺𝗅𝗅 𝖼𝗈𝗆𝗉𝗅𝖾𝗑 𝖾𝗅𝖾𝗆𝖾𝗇𝗍𝗌 𝖺𝗋𝖾 𝗉𝗋𝖾𝖿𝖺𝖻𝗋𝗂𝖼𝖺𝗍𝖾𝖽 𝗈𝖿𝖿-𝗌𝗂𝗍𝖾 𝗂𝗇 𝟥𝖣 𝗍𝗂𝗆𝖻𝖾𝗋 𝗆𝗈𝖽𝗎𝗅𝖾𝗌. 𝖳𝗁𝖾𝗌𝖾 𝖺𝗋𝖾 𝗍𝗁𝖾𝗇 𝖺𝗌𝗌𝖾𝗆𝖻𝗅𝖾𝖽 𝗈𝗇-𝗌𝗂𝗍𝖾 𝗍𝗈𝗀𝖾𝗍𝗁𝖾𝗋 𝗐𝗂𝗍𝗁 𝗌𝗂𝗆𝗉𝗅𝖾, 𝖿𝗅𝖾𝗑𝗂𝖻𝗅𝖾, 𝗉𝗋𝖾𝖿𝖺𝖻𝗋𝗂𝖼𝖺𝗍𝖾𝖽 𝟤𝖣 𝗉𝖺𝗇𝖾𝗅𝗌. 𝖨𝗇 𝗌𝗈-𝖽𝗈𝗂𝗇𝗀, 𝗐𝖾 𝗈𝗉𝗍𝗂𝗆𝖺𝗅𝗅𝗒 𝗅𝖾𝗏𝖾𝗋𝖺𝗀𝖾 𝗍𝗁𝖾 𝖻𝖾𝗇𝖾𝖿𝗂𝗍𝗌 𝗈𝖿 𝖽𝗂𝖿𝖿𝖾𝗋𝖾𝗇𝗍 𝗍𝗒𝗉𝖾𝗌 𝗈𝖿 𝗉𝗋𝖾𝖿𝖺𝖻𝗋𝗂𝖼𝖺𝗍𝗂𝗈𝗇.

𝖳𝗁𝗂𝗌 𝗁𝖾𝗅𝗉𝗌 𝗎𝗌 𝖻𝖾𝗍𝗍𝖾𝗋 𝗆𝖾𝖾𝗍 𝖼𝗁𝖺𝗅𝗅𝖾𝗇𝗀𝖾𝗌 𝗋𝖾𝗅𝖺𝗍𝖾𝖽 𝗍𝗈 𝖼𝗈𝗇𝗌𝗍𝗋𝗎𝖼𝗍𝗂𝗈𝗇 𝗌𝗄𝗂𝗅𝗅𝗌 𝗌𝗁𝗈𝗋𝗍𝖺𝗀𝖾𝗌, 𝗋𝖾𝗌𝗈𝗎𝗋𝖼𝖾 𝗌𝖼𝖺𝗋𝖼𝗂𝗍𝗒, 𝖧𝖲𝖤𝖰 𝗇𝖾𝖾𝖽𝗌, 𝖺𝗌 𝗐𝖾𝗅𝗅 𝖺𝗌 𝖾𝗆𝖻𝗋𝖺𝖼𝗂𝗇𝗀 𝗍𝗁𝖾 𝗈𝗉𝗉𝗈𝗋𝗍𝗎𝗇𝗂𝗍𝗂𝖾𝗌 𝗈𝖿𝖿𝖾𝗋𝖾𝖽 𝖻𝗒 𝖽𝗂𝗀𝗂𝗍𝖺𝗅 𝖿𝖺𝖻𝗋𝗂𝖼𝖺𝗍𝗂𝗈𝗇 & 𝗂𝗇𝖽𝗎𝗌𝗍𝗋𝗂𝖺𝗅𝗂𝗌𝖾𝖽 𝖼𝗈𝗇𝗌𝗍𝗋𝗎𝖼𝗍𝗂𝗈𝗇.