Project Revenues with Confidence

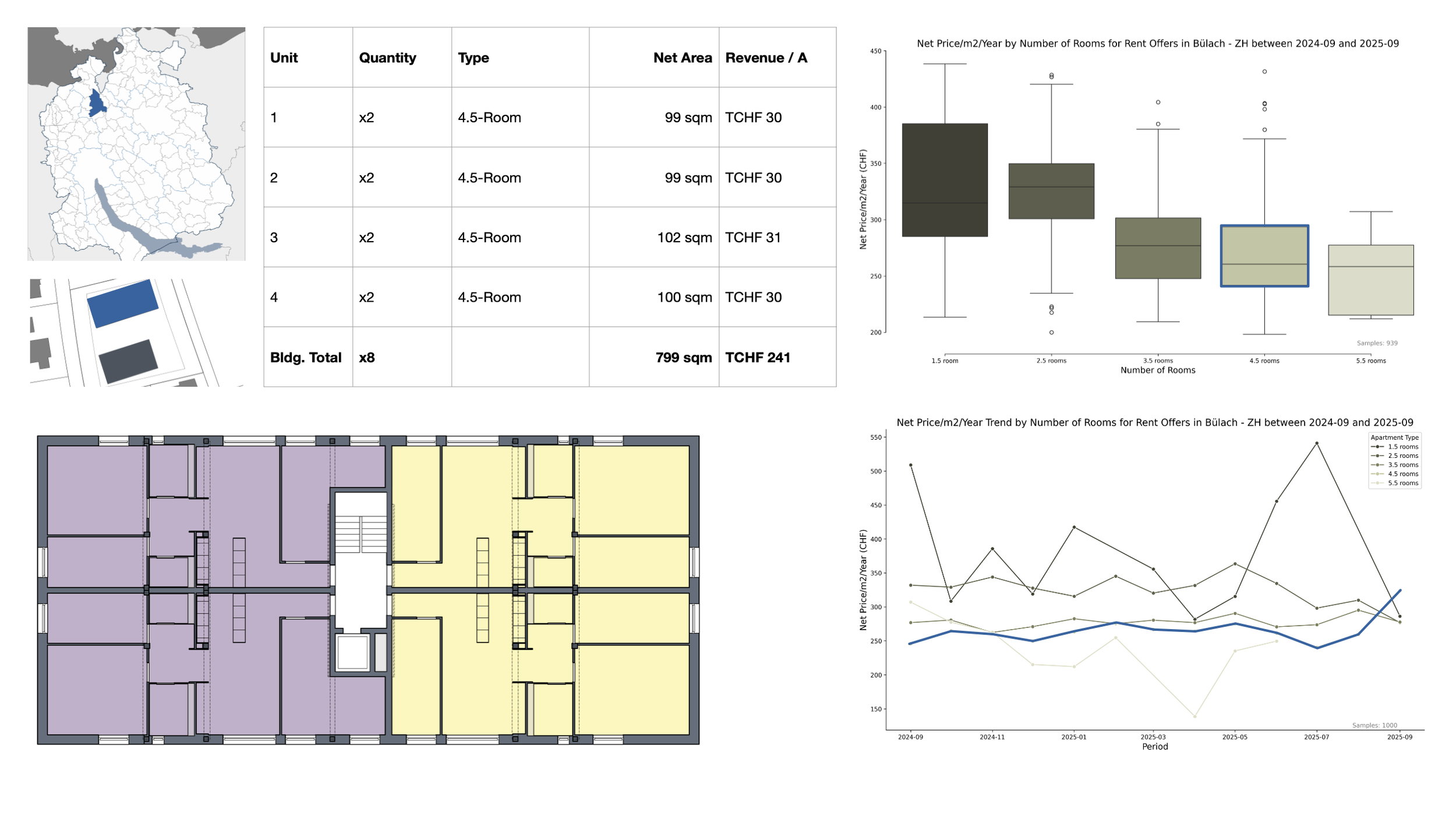

Projected revenues drive real estate projects. And yet, at the project outset, revenue estimates often rely on a whole host of assumptions, such as floor plan efficiency and an arbitrary unit mix. We want to sharpen those assumptions in a systematic and data-driven way.

Projected revenues drive real estate projects. And yet, at the project outset, revenue estimates often rely on a whole host of assumptions, such as floor plan efficiency and an arbitrary unit mix. We want to sharpen those assumptions in a systematic and data-driven way.

Thanks to our partnership with Semanta.ai, Rabbit Real Estate delivers precise revenue estimates from the very first feasibility study. Semanta.ai collects millions of real estate advertisements, enabling market-based revenue and trend estimates per sqm, unit type and location.

Together with our configurator and kit-of-parts, which generate functional floor plans for various unit mixes and sizes, we can calculate precise revenue estimates. This allows for better-informed decisions regarding programme, floor area efficiency and the choice of design options to optimise the business case.

No Surprises

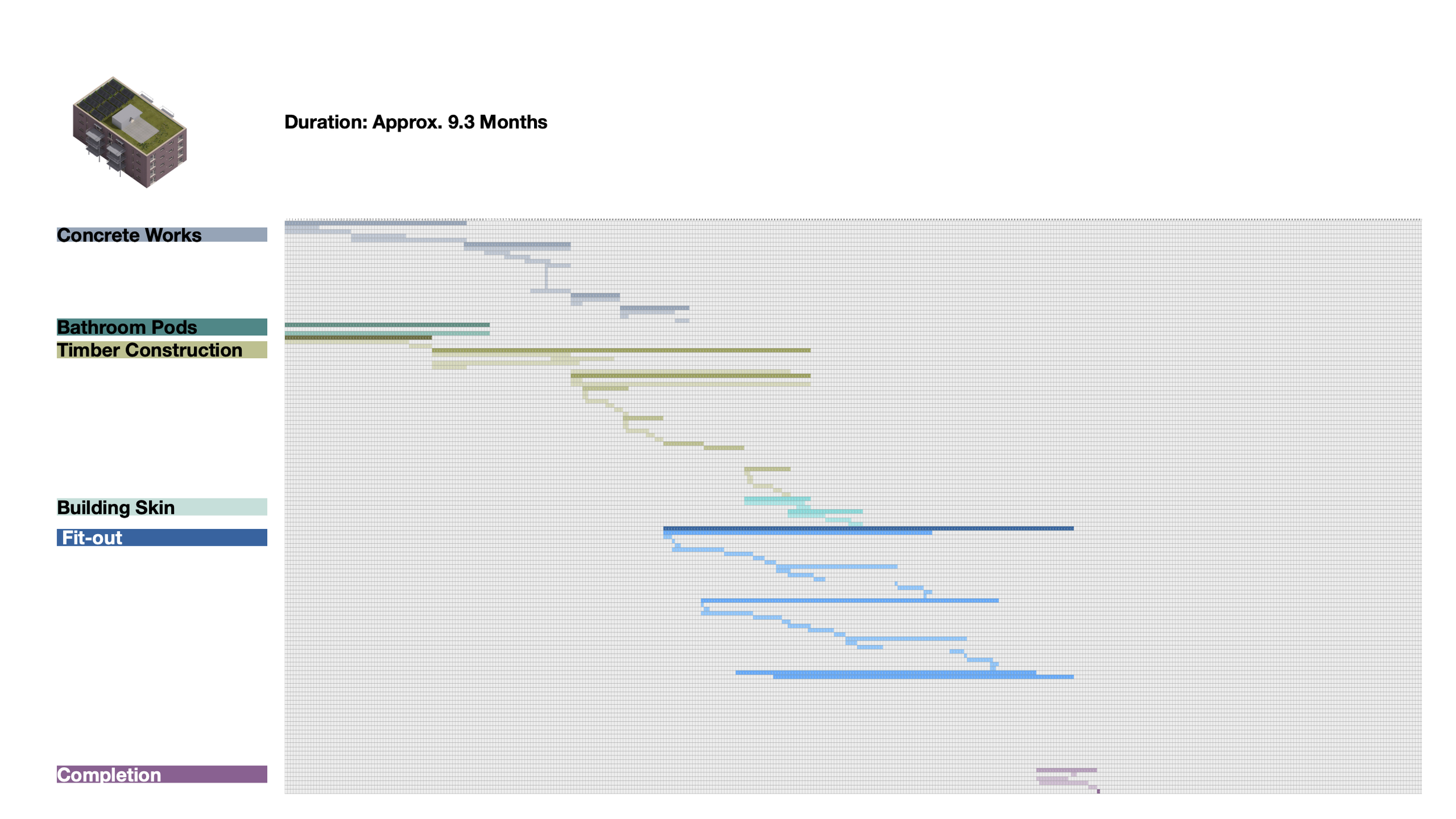

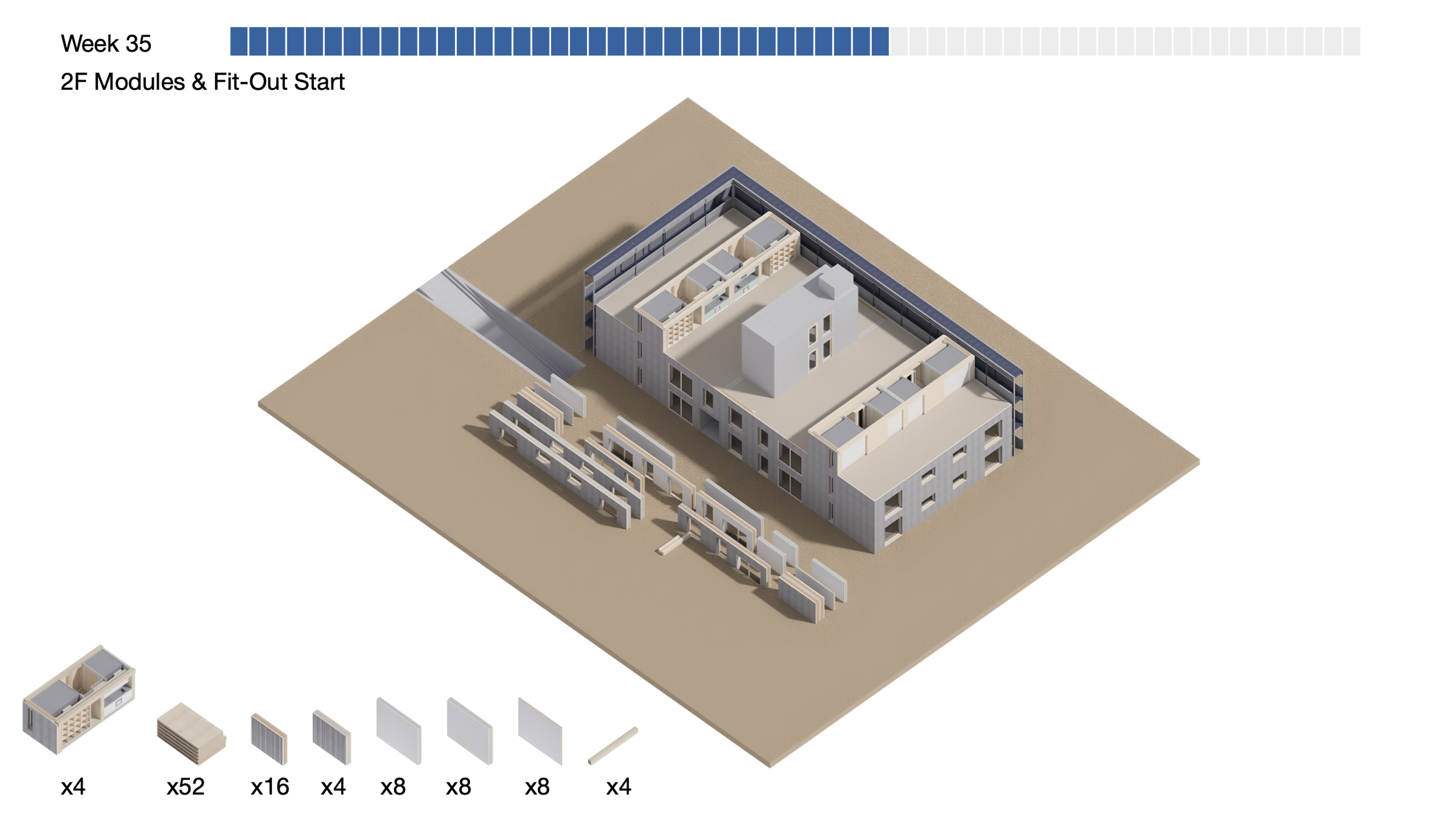

It's not implied by our name for nothing - we value speed. Not at the expense of quality, but in combination with agility, well-informed decision-making and foresight. In combination with a kit-of-parts, our scalable, industrialised construction approach allows us to plan ahead and do exactly that.

It's not implied by our name for nothing - we value speed. Not at the expense of quality, but in combination with agility, well-informed decision-making and foresight. In combination with a kit-of-parts, our scalable, industrialised construction approach allows us to plan ahead and do exactly that.

We match the automated bill of quantities from our configurator in the temporal dimension with production and assembly times for each on-site construction trade and off-site building element to produce dependable scheduling estimates at the feasibility study stage. Whilst these are not set in stone, they provide an early basis for refinement together with our delivery partners throughout the planning process - enhancing predictability and reducing risk.

Automated Bill of Quantities

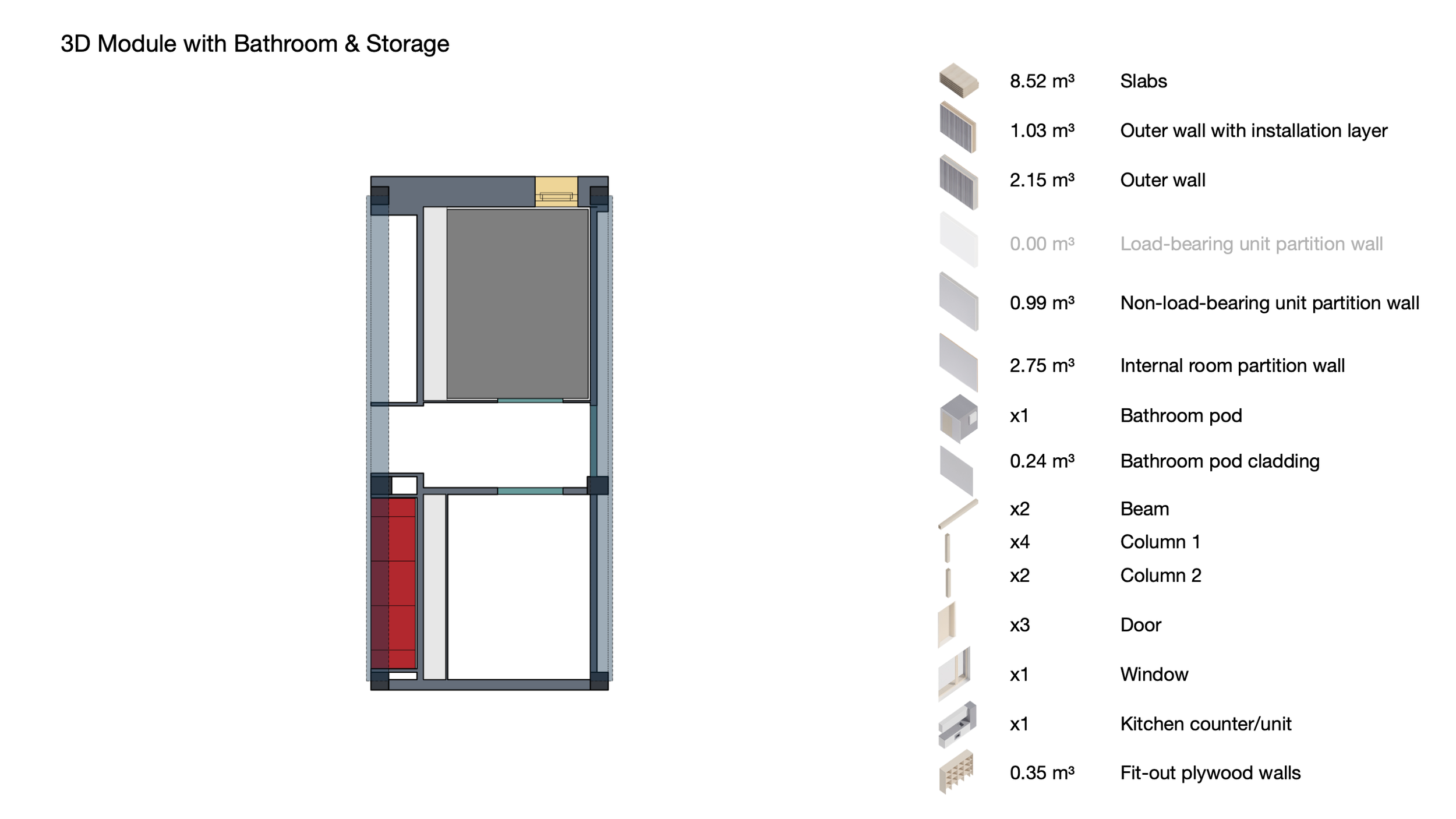

Prefabricated and systematised construction goes hand-in-hand with precise bills of quantities and element-based analyses. Gone are the days when projects had to rely on imprecise area and volume benchmarks that throw together different construction trades, materials and supply-chains.

Prefabricated and systematised construction goes hand-in-hand with precise bills of quantities and element-based analyses. Gone are the days when projects had to rely on imprecise area and volume benchmarks that throw together different construction trades, materials and supply-chains.

With our configurator and a kit-of-parts, we can accurately generate BoQs at the feasibility study stage and know exactly what goes into a project - element by element.

Stay tuned to see how we tie these to automated element-based cost, LCA and construction time estimates - all at a feasibility study stage.

Configure. Automate. Optimise.

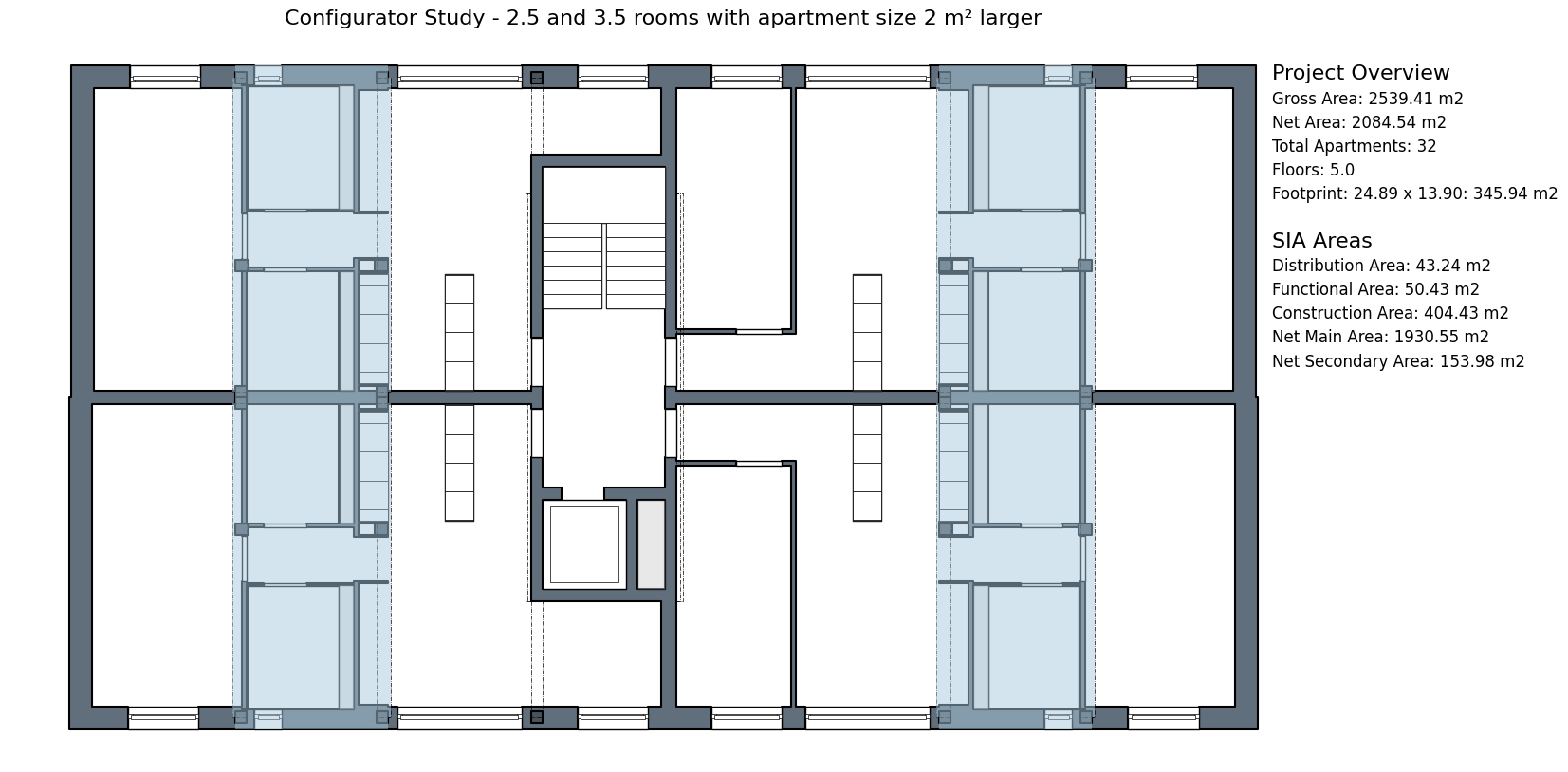

Our Python-based configurator uses a kit-of-parts to generate a wide range of potential floor plan solutions based on project inputs (target unit mix & sizes, plot geometry and the maximum realisable area or volume) within minutes.

Our Python-based configurator uses a kit-of-parts to generate a wide range of potential floor plan solutions based on project inputs (target unit mix & sizes, plot geometry and the maximum realisable area or volume) within minutes. This automated process includes key output metrics such as floor area categories, unit and room sizes.

Stay tuned to see how we use this approach to further optimise floor area efficiency and economic performance, as well as providing reliable data on costs, LCA and construction time - all at a feasibility study stage.

Variety in a Systematised Approach

Prefabrication and variety are not mutually-exclusive.

In fact, the design may even become richer - because it tells the story of how a building and its pieces were made and put together.

Prefabrication and variety are not mutually-exclusive. Whilst additional production and assembly constraints may restrict what is possible, site- & project-specific responses, regulatory and life-cycle considerations, as well as varied architectural expression in terms of material, rhythm, pattern, scale and colour, are all still possible.

In fact, the design may even become richer - because it tells the story of how a building and its pieces were made and put together.

Pre-fab is not what it used to be

Gone are the days when modular, pre-fabricated housing has to be associated with unfeeling and drab concrete boxes. This is what the new era of pre-fab looks and feels like.

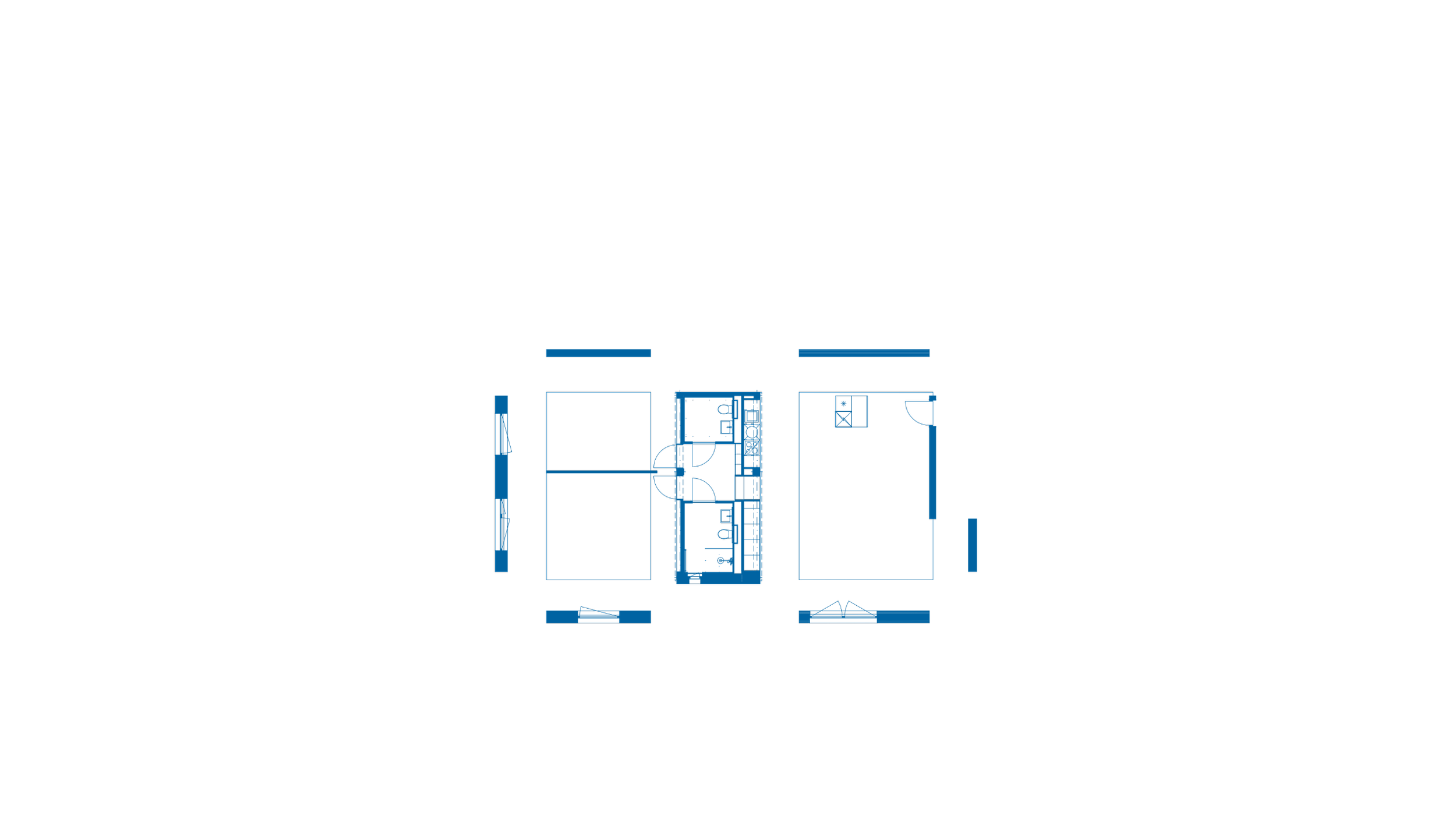

Visual of a 4-room corner unit

Visual of a 3-room through-put unit

Gone are the days when modular, pre-fabricated housing has to be associated with unfeeling and drab concrete boxes. Pre-fabricated timber construction is not only more lightweight and sustainable, but creates a warm atmosphere with natural surfaces and a beneficial indoor climate. The simple and honest structural design is made legible in the exposed columns and beams that also delineate interior spaces.

Our partners' innovative manufacturing processes and our system-based approach also allow for a range of configurable interior design lines with variable ceiling and floor materialities, colour ranges and built-in furniture modules.

This is what the new era of pre-fab looks and feels like.

Tick-Tock

We strive towards a ~30% reduction in on-site construction time compared to conventional construction methods - and this figure can only get better with every new project.

We strive towards a ~30% reduction in on-site construction time compared to conventional construction methods - and this figure can only get better with every new project.

Why? Because every completed project provides us and our partners with valuable feedback that enables us to incrementally re-engineer our product and refine our process, improving speed, quality and cost.

It is this structured learning and continuous improvement that differentiates a systems-based approach from a one-off project.

Best of both Worlds: 3D Modular & 2D Panelised

𝖶𝖾 𝗎𝗌𝖾 𝖺 𝖼𝗈𝗇𝗌𝗍𝗋𝗎𝖼𝗍𝗂𝗈𝗇 𝗌𝗒𝗌𝗍𝖾𝗆 𝗂𝗇 𝗐𝗁𝗂𝖼𝗁 𝖺𝗅𝗅 𝖼𝗈𝗆𝗉𝗅𝖾𝗑 𝖾𝗅𝖾𝗆𝖾𝗇𝗍𝗌 𝖺𝗋𝖾 𝗉𝗋𝖾𝖿𝖺𝖻𝗋𝗂𝖼𝖺𝗍𝖾𝖽 𝗈𝖿𝖿-𝗌𝗂𝗍𝖾 𝗂𝗇 𝟥𝖣 𝗍𝗂𝗆𝖻𝖾𝗋 𝗆𝗈𝖽𝗎𝗅𝖾𝗌. 𝖳𝗁𝖾𝗌𝖾 𝖺𝗋𝖾 𝗍𝗁𝖾𝗇 𝖺𝗌𝗌𝖾𝗆𝖻𝗅𝖾𝖽 𝗈𝗇-𝗌𝗂𝗍𝖾 𝗍𝗈𝗀𝖾𝗍𝗁𝖾𝗋 𝗐𝗂𝗍𝗁 𝗌𝗂𝗆𝗉𝗅𝖾, 𝖿𝗅𝖾𝗑𝗂𝖻𝗅𝖾, 𝗉𝗋𝖾𝖿𝖺𝖻𝗋𝗂𝖼𝖺𝗍𝖾𝖽 𝟤𝖣 𝗉𝖺𝗇𝖾𝗅𝗌. 𝖨𝗇 𝗌𝗈-𝖽𝗈𝗂𝗇𝗀, 𝗐𝖾 𝗈𝗉𝗍𝗂𝗆𝖺𝗅𝗅𝗒 𝗅𝖾𝗏𝖾𝗋𝖺𝗀𝖾 𝗍𝗁𝖾 𝖻𝖾𝗇𝖾𝖿𝗂𝗍𝗌 𝗈𝖿 𝖽𝗂𝖿𝖿𝖾𝗋𝖾𝗇𝗍 𝗍𝗒𝗉𝖾𝗌 𝗈𝖿 𝗉𝗋𝖾𝖿𝖺𝖻𝗋𝗂𝖼𝖺𝗍𝗂𝗈𝗇.

𝖶𝖾 𝗎𝗌𝖾 𝖺 𝖼𝗈𝗇𝗌𝗍𝗋𝗎𝖼𝗍𝗂𝗈𝗇 𝗌𝗒𝗌𝗍𝖾𝗆 𝗂𝗇 𝗐𝗁𝗂𝖼𝗁 𝖺𝗅𝗅 𝖼𝗈𝗆𝗉𝗅𝖾𝗑 𝖾𝗅𝖾𝗆𝖾𝗇𝗍𝗌 𝖺𝗋𝖾 𝗉𝗋𝖾𝖿𝖺𝖻𝗋𝗂𝖼𝖺𝗍𝖾𝖽 𝗈𝖿𝖿-𝗌𝗂𝗍𝖾 𝗂𝗇 𝟥𝖣 𝗍𝗂𝗆𝖻𝖾𝗋 𝗆𝗈𝖽𝗎𝗅𝖾𝗌. 𝖳𝗁𝖾𝗌𝖾 𝖺𝗋𝖾 𝗍𝗁𝖾𝗇 𝖺𝗌𝗌𝖾𝗆𝖻𝗅𝖾𝖽 𝗈𝗇-𝗌𝗂𝗍𝖾 𝗍𝗈𝗀𝖾𝗍𝗁𝖾𝗋 𝗐𝗂𝗍𝗁 𝗌𝗂𝗆𝗉𝗅𝖾, 𝖿𝗅𝖾𝗑𝗂𝖻𝗅𝖾, 𝗉𝗋𝖾𝖿𝖺𝖻𝗋𝗂𝖼𝖺𝗍𝖾𝖽 𝟤𝖣 𝗉𝖺𝗇𝖾𝗅𝗌. 𝖨𝗇 𝗌𝗈-𝖽𝗈𝗂𝗇𝗀, 𝗐𝖾 𝗈𝗉𝗍𝗂𝗆𝖺𝗅𝗅𝗒 𝗅𝖾𝗏𝖾𝗋𝖺𝗀𝖾 𝗍𝗁𝖾 𝖻𝖾𝗇𝖾𝖿𝗂𝗍𝗌 𝗈𝖿 𝖽𝗂𝖿𝖿𝖾𝗋𝖾𝗇𝗍 𝗍𝗒𝗉𝖾𝗌 𝗈𝖿 𝗉𝗋𝖾𝖿𝖺𝖻𝗋𝗂𝖼𝖺𝗍𝗂𝗈𝗇.

𝖳𝗁𝗂𝗌 𝗁𝖾𝗅𝗉𝗌 𝗎𝗌 𝖻𝖾𝗍𝗍𝖾𝗋 𝗆𝖾𝖾𝗍 𝖼𝗁𝖺𝗅𝗅𝖾𝗇𝗀𝖾𝗌 𝗋𝖾𝗅𝖺𝗍𝖾𝖽 𝗍𝗈 𝖼𝗈𝗇𝗌𝗍𝗋𝗎𝖼𝗍𝗂𝗈𝗇 𝗌𝗄𝗂𝗅𝗅𝗌 𝗌𝗁𝗈𝗋𝗍𝖺𝗀𝖾𝗌, 𝗋𝖾𝗌𝗈𝗎𝗋𝖼𝖾 𝗌𝖼𝖺𝗋𝖼𝗂𝗍𝗒, 𝖧𝖲𝖤𝖰 𝗇𝖾𝖾𝖽𝗌, 𝖺𝗌 𝗐𝖾𝗅𝗅 𝖺𝗌 𝖾𝗆𝖻𝗋𝖺𝖼𝗂𝗇𝗀 𝗍𝗁𝖾 𝗈𝗉𝗉𝗈𝗋𝗍𝗎𝗇𝗂𝗍𝗂𝖾𝗌 𝗈𝖿𝖿𝖾𝗋𝖾𝖽 𝖻𝗒 𝖽𝗂𝗀𝗂𝗍𝖺𝗅 𝖿𝖺𝖻𝗋𝗂𝖼𝖺𝗍𝗂𝗈𝗇 & 𝗂𝗇𝖽𝗎𝗌𝗍𝗋𝗂𝖺𝗅𝗂𝗌𝖾𝖽 𝖼𝗈𝗇𝗌𝗍𝗋𝗎𝖼𝗍𝗂𝗈𝗇.

Welcome to Mass Customisation in Real Estate

𝖶𝗂𝗍𝗁 𝖺 𝗉𝗋𝖾-𝖽𝖾𝗌𝗂𝗀𝗇𝖾𝖽 𝗌𝗒𝗌𝗍𝖾𝗆, 𝗐𝖾 𝖺𝗋𝖾 𝖺𝖻𝗅𝖾 𝗍𝗈 𝖼𝗈𝗇𝖿𝗂𝗀𝗎𝗋𝖾 𝖺𝗇𝖽 𝖼𝗁𝗈𝗈𝗌𝖾 𝖿𝗋𝗈𝗆 𝗍𝗁𝗈𝗎𝗌𝖺𝗇𝖽𝗌 𝗈𝖿 𝗉𝗈𝗍𝖾𝗇𝗍𝗂𝖺𝗅 𝗁𝗈𝗎𝗌𝗂𝗇𝗀 𝗎𝗇𝗂𝗍 𝗅𝖺𝗒𝗈𝗎𝗍𝗌 𝗀𝖾𝗇𝖾𝗋𝖺𝗍𝖾𝖽 𝖿𝗋𝗈𝗆 𝖺 𝗌𝗂𝗇𝗀𝗅𝖾 𝗄𝗂𝗍-𝗈𝖿-𝗉𝖺𝗋𝗍𝗌.

𝖶𝗂𝗍𝗁 𝖺 𝗉𝗋𝖾-𝖽𝖾𝗌𝗂𝗀𝗇𝖾𝖽 𝗌𝗒𝗌𝗍𝖾𝗆, 𝗐𝖾 𝖺𝗋𝖾 𝖺𝖻𝗅𝖾 𝗍𝗈 𝖼𝗈𝗇𝖿𝗂𝗀𝗎𝗋𝖾 𝖺𝗇𝖽 𝖼𝗁𝗈𝗈𝗌𝖾 𝖿𝗋𝗈𝗆 𝗍𝗁𝗈𝗎𝗌𝖺𝗇𝖽𝗌 𝗈𝖿 𝗉𝗈𝗍𝖾𝗇𝗍𝗂𝖺𝗅 𝗁𝗈𝗎𝗌𝗂𝗇𝗀 𝗎𝗇𝗂𝗍 𝗅𝖺𝗒𝗈𝗎𝗍𝗌𝗀𝖾𝗇𝖾𝗋𝖺𝗍𝖾𝖽 𝖿𝗋𝗈𝗆 𝖺 𝗌𝗂𝗇𝗀𝗅𝖾 𝗄𝗂𝗍-𝗈𝖿-𝗉𝖺𝗋𝗍𝗌.

𝖳𝗁𝗂𝗌 𝖺𝗅𝗅𝗈𝗐𝗌 𝗎𝗌 𝗍𝗈 𝗊𝗎𝗂𝖼𝗄𝗅𝗒 𝖾𝗏𝖺𝗅𝗎𝖺𝗍𝖾 𝗍𝗁𝖾 𝖿𝗎𝗅𝗅 𝗋𝖺𝗇𝗀𝖾 𝗈𝖿 𝖺𝗏𝖺𝗂𝗅𝖺𝖻𝗅𝖾 𝗈𝗉𝗍𝗂𝗈𝗇𝗌 𝗂𝗇 𝖺𝗇 𝖾𝖺𝗋𝗅𝗒 𝗌𝗍𝗋𝖺𝗍𝖾𝗀𝗂𝖼 𝗉𝗁𝖺𝗌𝖾 𝗂𝗇 𝗈𝗋𝖽𝖾𝗋 𝗍𝗈 𝗆𝖺𝗄𝖾𝖻𝖾𝗍𝗍𝖾𝗋-𝗂𝗇𝖿𝗈𝗋𝗆𝖾𝖽 𝖽𝖾𝖼𝗂𝗌𝗂𝗈𝗇𝗌.