Top-down & Bottom-up

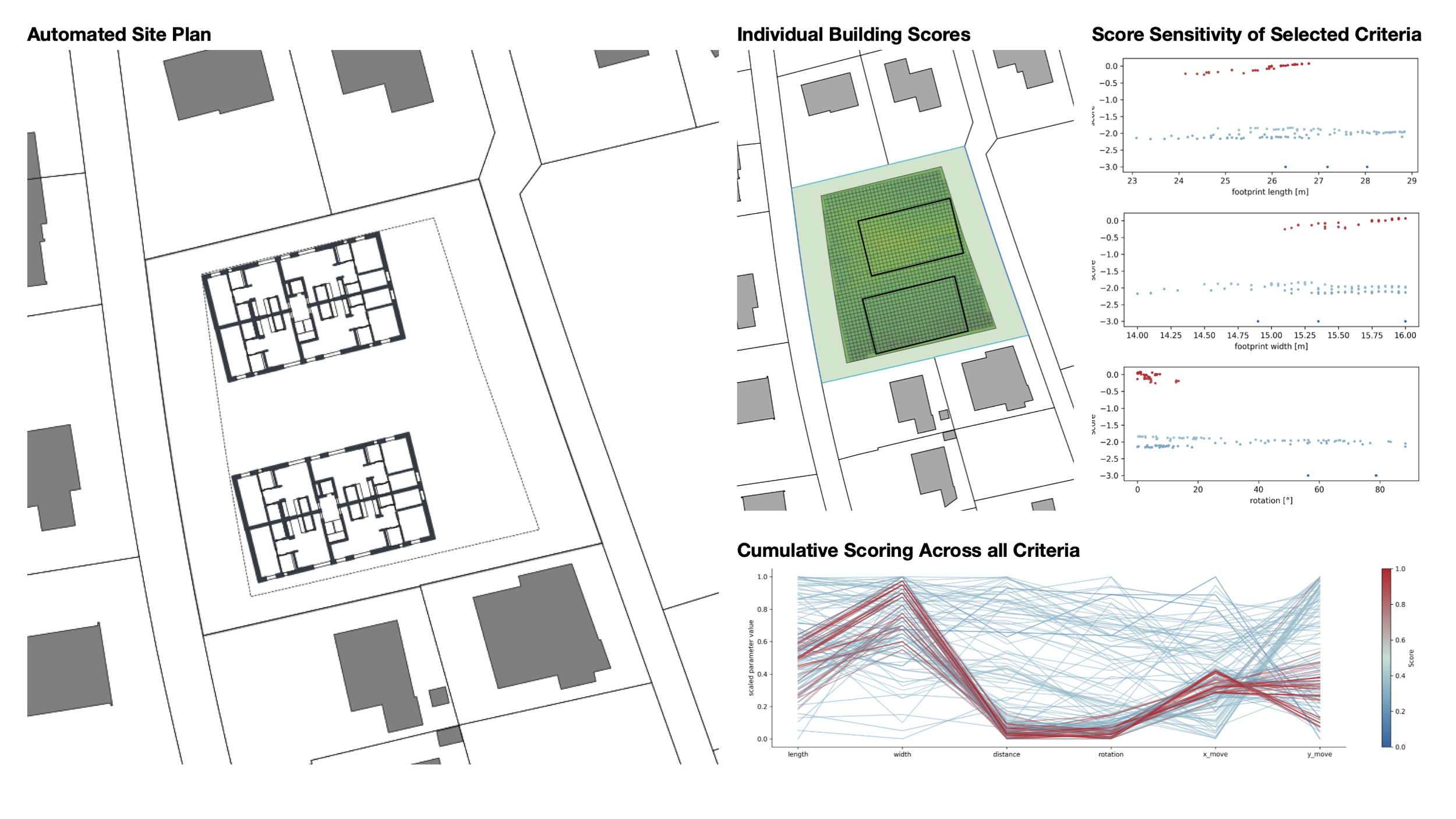

Optimising a housing project is a complex, iterative process. It requires a great deal of fine-tuning and cross-scalar trade-offs between different goals and parameters. Our configurator helps expedite this by automating and evaluating iterations according to a scoring system.

Optimising a housing project is a complex, iterative process. It requires a great deal of fine-tuning and cross-scalar trade-offs between different goals and parameters.

Our configurator helps expedite this by automating and evaluating iterations according to a scoring system. Building volumes are simultaneously positioned "top-down" in response to geo data, spatial analysis and planning regulations, whilst also laid out "bottom-up" using a single kit-of-parts within a modular construction system.

Together, this multi-scalar approach maximises plot utilisation and floor area efficiency, provides the ideal unit mix and thereby optimises risk-adjusted returns. This is just one way in which we want to make decision-making more dependably data-driven.

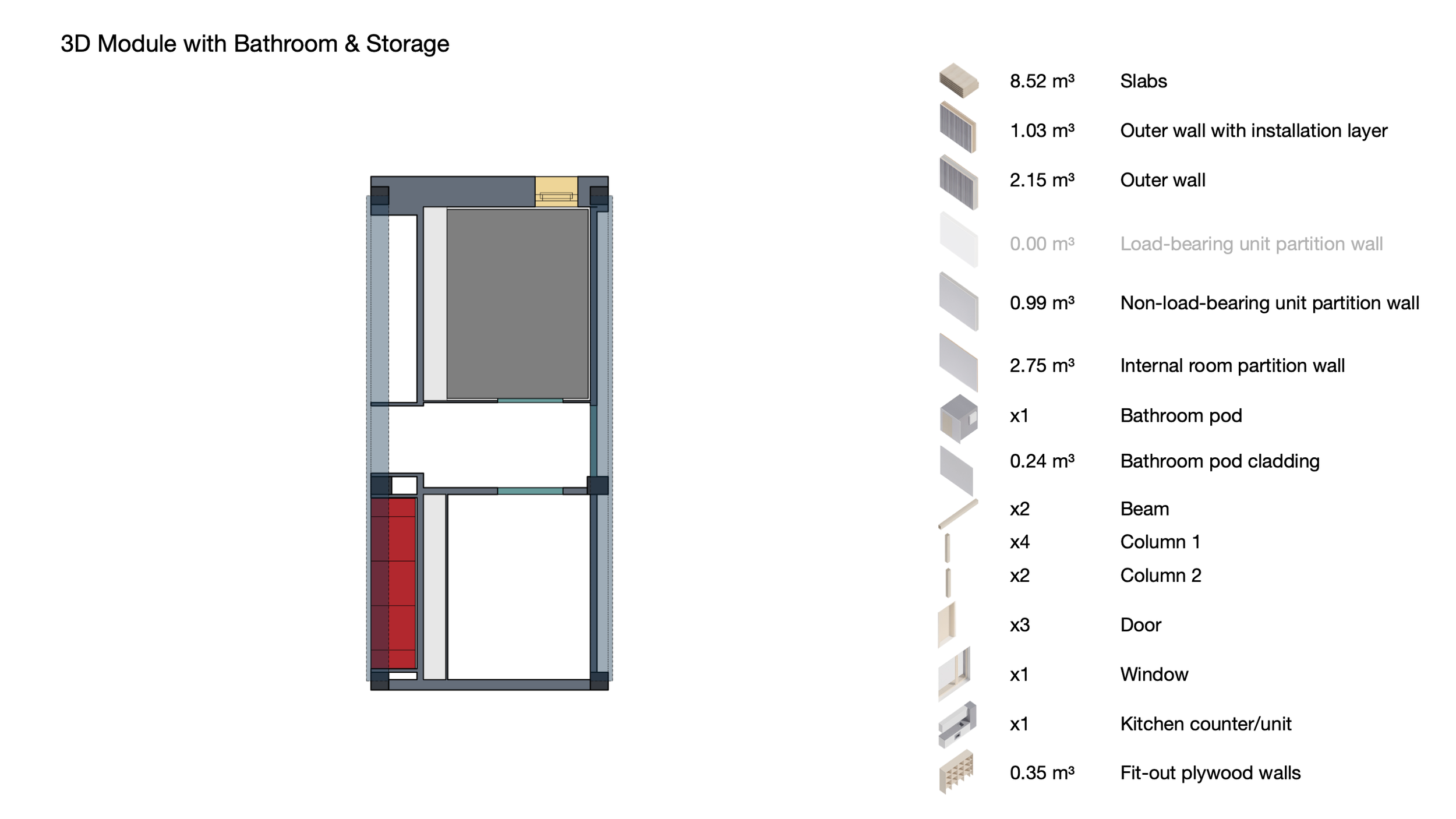

Automated Bill of Quantities

Prefabricated and systematised construction goes hand-in-hand with precise bills of quantities and element-based analyses. Gone are the days when projects had to rely on imprecise area and volume benchmarks that throw together different construction trades, materials and supply-chains.

Prefabricated and systematised construction goes hand-in-hand with precise bills of quantities and element-based analyses. Gone are the days when projects had to rely on imprecise area and volume benchmarks that throw together different construction trades, materials and supply-chains.

With our configurator and a kit-of-parts, we can accurately generate BoQs at the feasibility study stage and know exactly what goes into a project - element by element.

Stay tuned to see how we tie these to automated element-based cost, LCA and construction time estimates - all at a feasibility study stage.

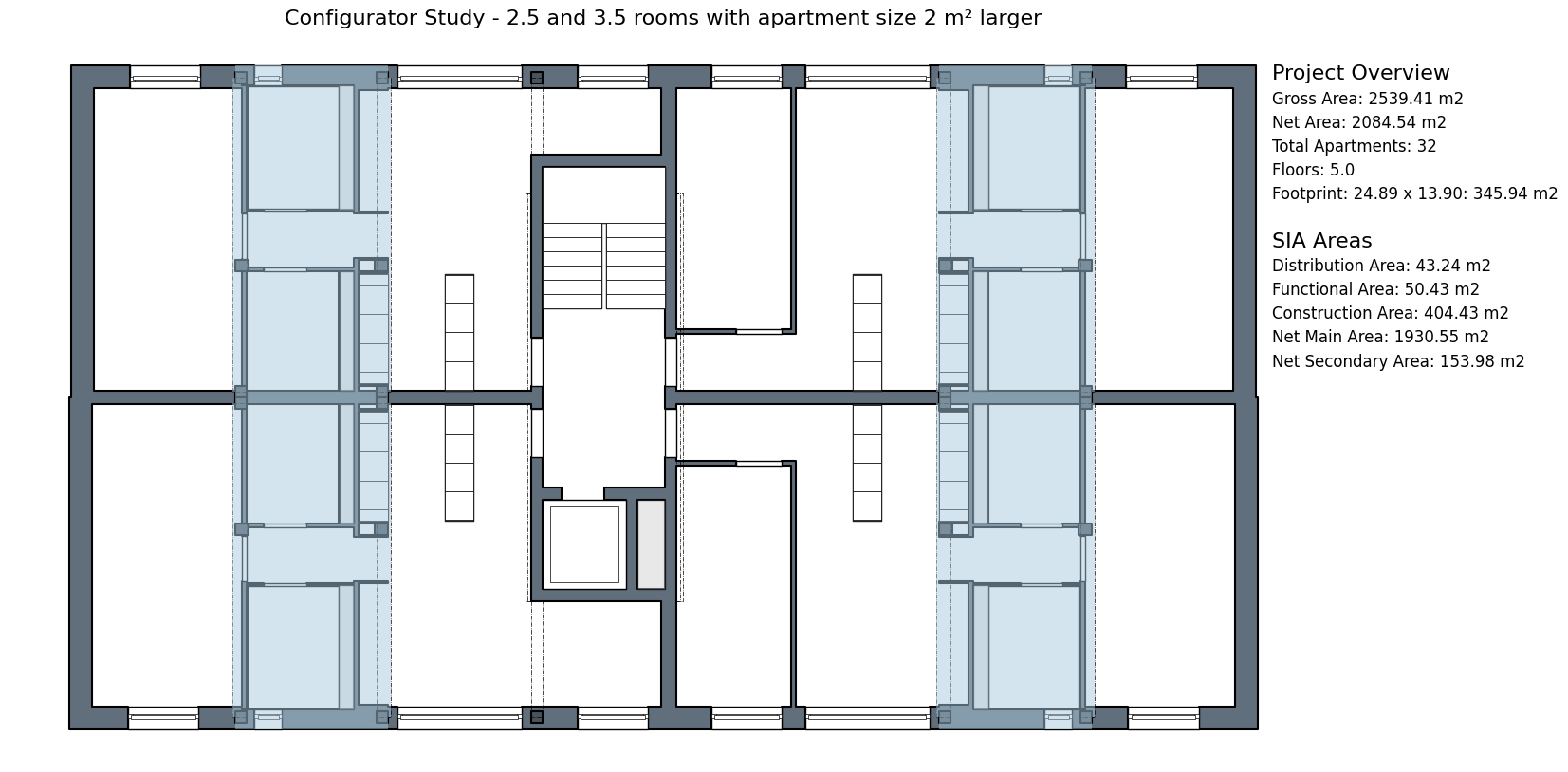

Configure. Automate. Optimise.

Our Python-based configurator uses a kit-of-parts to generate a wide range of potential floor plan solutions based on project inputs (target unit mix & sizes, plot geometry and the maximum realisable area or volume) within minutes.

Our Python-based configurator uses a kit-of-parts to generate a wide range of potential floor plan solutions based on project inputs (target unit mix & sizes, plot geometry and the maximum realisable area or volume) within minutes. This automated process includes key output metrics such as floor area categories, unit and room sizes.

Stay tuned to see how we use this approach to further optimise floor area efficiency and economic performance, as well as providing reliable data on costs, LCA and construction time - all at a feasibility study stage.